- Gala No. 19, 2nd Floor,

Bail Bazar, Mumbai, India - +91 88 5002 0455

info@alfafans.in

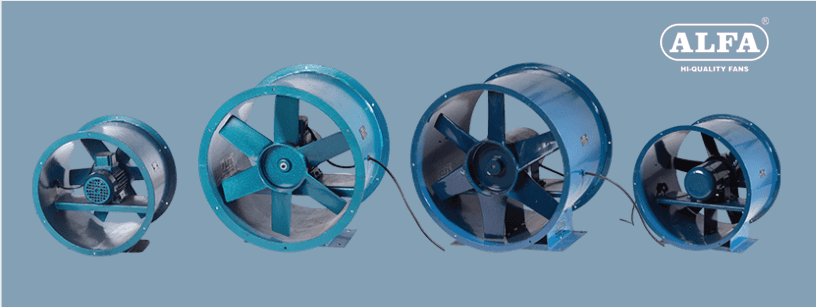

Disclosing the secret of fresh air with Tube Axial Fan. The operating principle of the axial fan is that the direction of air flow is parallel to the rotor shaft. The blades of the fans force air linearly to the shaft. This creates a high flow rate, and helps to achieve a bigger volume of air flow. In this operation, the air movements created are of lower pressure and generally require lower power input for operation.

How do Tube Axial Fans Operate?

These tube axial fans are best suited for low air resistance and high flow usage conditions.

There is a wide variation of axial fans in industry depending on the final usage. The blades can

be forward curved, straight or backward curved. There is greater efficiency when the blades

are curved backwards than the forward curved blades, but it has also been recorded that the

forward oriented blades are better at self-cleaning than the backward oriented.

Features of Axial Fans

The most distinguishing component of the axial fan is the axial impeller with the number of

blades ranging from 2 to 20 depending on the design and performance requirements. This is

connected to a powerful drive motor, and these are assembled in a housing designed for parallel

flow of air through the fan.

These fans are highly energy efficient with the ability to generate greater air movement using

considerably less energy, and therefore high cost savings to users. When compared to other

types of fans, they are able to offer up to 40% savings on power usage

Factors Affecting Axial Fans Performance

Several design factors affect the performance of the axial fans and these include;

● Density or weight of air per unit volume

● Number of blades in the unit; this is the ratio of the sum of blade widths to the fan’s

circumference

● Shape of the blade. Be it straight, curved, forward or backward orientation. The blade

shape

affects the air flow on and across the surface of the fan. The shape twists the air and affects the

velocity and air profile

Industrial applications:

The design of these industrial fans is essentially to create an air pressure alteration in the fan.

They are manufactured from aluminum alloys and non sparkling iron.

Alfa's Tube Axial Flow fan system uses blades (propellers) to generate airflow that is parallel

to the shaft through which the blades rotate. It's one of the best products designed by the

company for the industrial & commercial sectors.

Axial fans are used in process applications where space is at a premium. Air flows through fans

parallel to the shaft moving outward in the same direction it flowed inward. These fans are

used for creating a high volume of airflow in lower pressure applications.

Applications for Axial Flow Fans include:

● Paint spray booth exhaust.

● To exhaust dangerous fumes away from the operator.

● Welding fume exhaust in welding booths.

● Process cooling and exhaust of machinery and/or systems.

● Spot cooling of heat generating equipment such as generators or transformers.

● Proper ventilation using supply air and/or make-up air in factories, warehouses, foundries

garages, laundries and transformer, engine or equipment rooms.

● People cooling in hot work areas.

● Exhausting heat and cooling of kilns, forges and in steel mills.

● Boosting airflow through long ductwork.

● Exhausting mist and vapor in paper mills or industrial parts washers prior to painting

parts