- Gala No. 19, 2nd Floor,

Bail Bazar, Mumbai, India - +91 88 5002 0455

info@alfafans.in

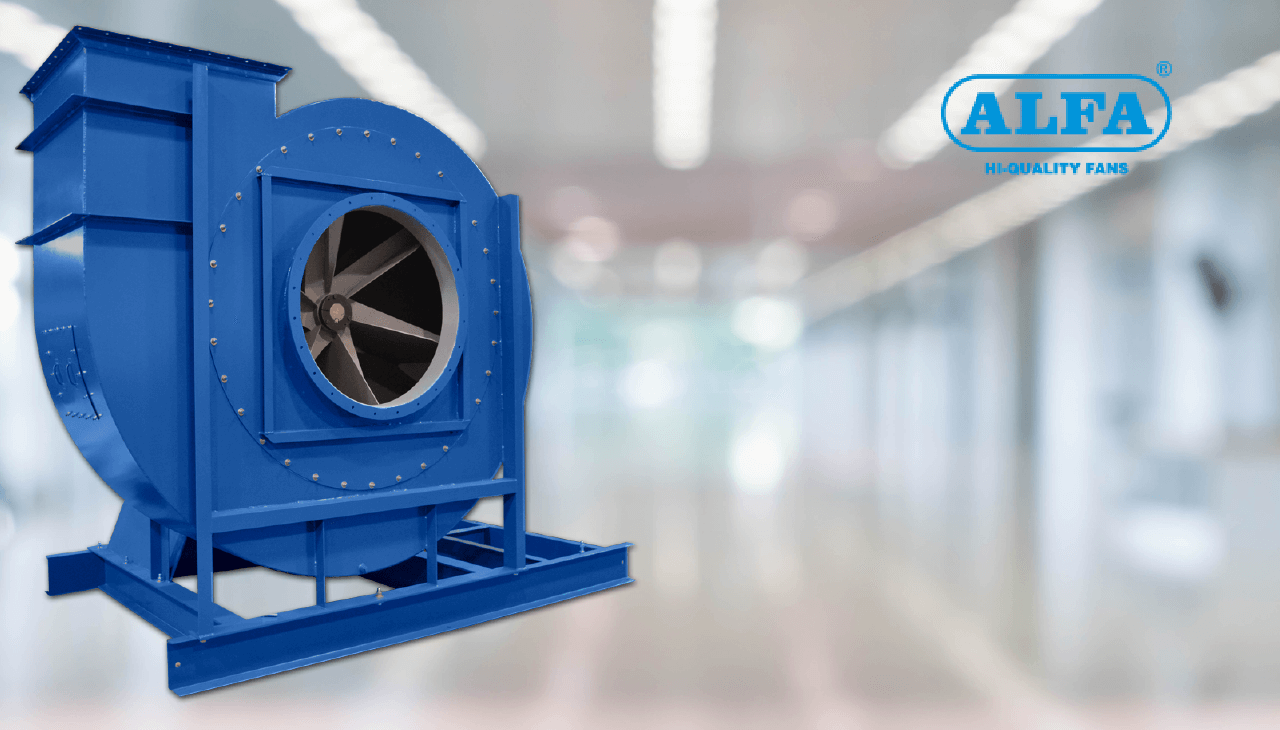

Centrifugal Fan Blade Types

Centrifugal fans come in four fundamental

Outspread These are high-pressure industrial fans with medium wind current. Spiral bladed fans are best for mechanical applications where there is dust, or in conditions where there is gas or dampness noticeable all around.

Forward Curve These are medium pressing factor, high wind stream fans that can be utilized in both clean air, ventilating and exhaust applications.

In reverse Curve These are high-pressure, high stream, high productivity fans. Force lessens as stream increments over the most productive territory of the framework.

Airfoil These are the most elevated proficiency fans, best in clean air applications.

Speed Requirements

To pick the suitable blower, you'll need to realize how much pressing factor is needed to arrive at the ideal wind stream to move air through the ducting and any channels, dampers or different obstacles in your ventilation framework. On the off chance that you have a long, confounded conduit framework, you'll obviously require much more force. Consider the effect of channels on the wind current too as this will likewise affect the pressing factor and force required.

Direct Drive is more average on more modest blowers and for the most part offers lower cost, less segments to collect, more prominent effectiveness (no drive misfortunes), decreased support (no different heading or belts) and more noteworthy unwavering quality.

Belt Drive offers more prominent adaptability in coordinating wind current necessities when furnished with a variable pitch engine pulley and is commonplace of bigger blowers. At the point when outfitted with a variable recurrence drive (three-stage blowers), direct drive blowers can offer the adaptability of belt drive blowers.

Climate

The climate wherein the framework works should likewise be considered to pick the correct blower-engine mix.

Outside Consider a Totally Enclosed Fan Cooled (TEFC) electric engine on direct drive units, or a belt drive unit with an included climate cover.

Messy or Dusty Environment A TEFC engine is best for longer life and ideal effectiveness.

Destructive Environment In wet, moist conditions, a tempered steel blower is suggested, ideally with a pure wash-obligation engine.

Unsafe Environment Consider a non-starting blower, for example, a spiral or

Air Quality

Clean Air Consider a forward bend, in reverse slope or airfoil blower for expanded effectiveness.

Daintily Dusty Air Consider an outspread or high-pressure blower. For light, non-rough cleans, a retrogressive slanted blower is worthy.

Heavier, More Abrasive Dust, Filings and Shavings For this climate, you'll likely need a modern material giving blower.

Destructive In wet, sticky, destructive conditions, you ought to pick a tempered steel blower, ideally with an impeccable wash-obligation engine.

Flammable If there's burnable residue or particulate noticeable all around, decide on a non-starting blower, for example, a spiral or high-pressure blower with a blast confirmation engine.

Air Temperatures Use belt drive units with steel wheels in higher temperatures. In the event that temperatures move above 250°F, think about a mechanical blower with a warmth slinger.

Assignment for Rotation and Direction of Discharge

The heading of the turn is resolved from the drive side of the fan. On single bay fans, the drive side is the side inverse of the fan gulf. On twofold delta fans with drives on the two sides, the drive side ought to be on a similar side as the more powerful drive unit.