11

November

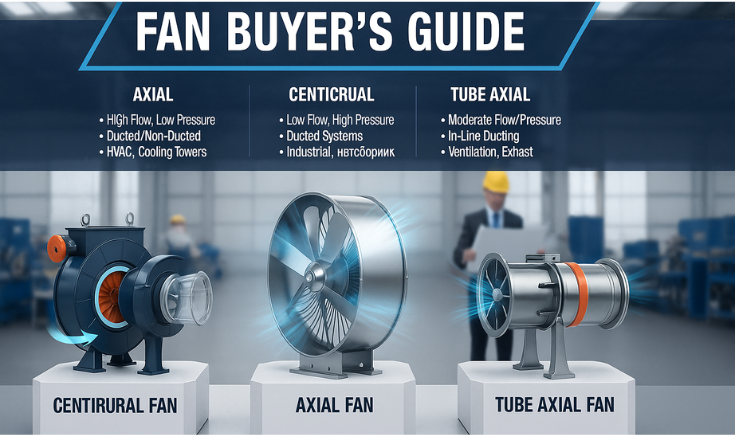

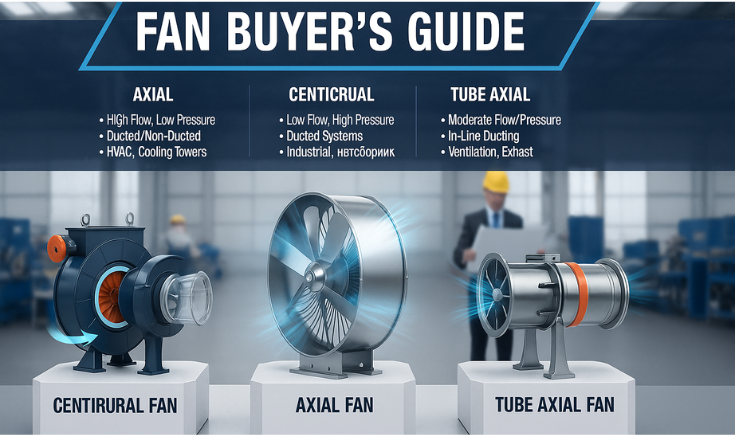

Choosing Between Axial, Centrifugal, and Tube Axial Fans: A Complete Buyer’s Guide

- November, 2025

- Alfa Fans

- BUYER'S GUIDE

Why the Right Industrial Fan Matters

In industrial and warehouse environments, ventilation efficiency affects both productivity and energy costs. Selecting the right fan ensures proper airflow, temperature control, and safety.

The three main fan types — axial, centrifugal, and tube axial - each move air differently and suit specific setups. Here’s how to choose the right one for your application.

Axial Fans - High Air Volume, Low Pressure

Axial fans move air parallel to the shaft, like a propeller. They’re ideal for large spaces needing steady air circulation.

- Applications: Warehouses, cooling towers, factories, workshops.

- Pros: High airflow at low energy use, compact and lightweight, easy maintenance.

- Cons: Not effective for high-pressure or long duct systems.

- Best for: Open areas with minimal airflow resistance.

Centrifugal Fans - High Pressure, Targeted Airflow

Centrifugal fans draw air in through the center and expel it perpendicular to the shaft. This boosts air pressure, making them ideal for ducted systems.

- Applications: HVAC systems, dust collectors, boilers, furnaces.

- Pros: Handles high resistance efficiently, suitable for long ducts and filters, quieter in enclosed setups.

- Cons: Heavier and higher energy consumption.

- Best for: Ventilation systems needing strong, focused airflow.

Tube Axial Fans - Compact and Directional

A tube axial fan is an axial fan mounted in a cylindrical housing, improving airflow direction and moderate pressure handling.

- Applications: Paint booths, tunnels, fume exhaust, ducted ventilation.

- Pros: Space-saving and compact, slightly higher efficiency than open axial fans, easy to install in ducts.

- Cons: Moderate pressure capability only.

- Best for: Confined or ducted zones needing controlled airflow.

Quick Comparison

| Feature |

Axial |

Centrifugal |

Tube Axial |

| Airflow Direction |

Parallel |

Perpendicular |

Parallel |

| Pressure Handling |

Low |

High |

Medium |

| Efficiency |

High (open air) |

High (ducted) |

Moderate |

| Noise Level |

Moderate |

Low |

Moderate |

| Ideal Use |

Large open space |

Ducted/high resistance |

Confined ducted area |

Energy Efficiency and Sustainability

Modern fans use energy-efficient motors and aerodynamic blades to cut power use by up to 30%. Adding VFD controls or IoT sensors can further improve performance and predictive maintenance.

Selecting the right fan type not only improves air quality but also supports your facility’s sustainability and ESG goals.

Why Choose Alfa Fans

At Alfa Fans, we design and manufacture a full range of axial, centrifugal, and tube axial fans built for Indian conditions - from warehouses to heavy industrial plants.

Our team helps you:

- Assess airflow and pressure needs

- Choose the right fan configuration

- Optimize energy efficiency

Contact Alfa Fans today to customize a high-performance ventilation system for your plant or warehouse.

Conclusion

Choosing wisely ensures better air movement, lower energy bills, and a safer workspace - with Alfa Fans as your trusted partner in industrial ventilation.

- Axial Fans: Best for large, open areas needing high air volume.

- Centrifugal Fans: Ideal for high-pressure, ducted systems.

- Tube Axial Fans: Perfect for confined, directional airflow zones.

Frequently Asked Questions

Axial fans move air parallel to the fan shaft and are best for high air volume at low pressure in open spaces. Centrifugal fans move air perpendicular to the shaft, generating high pressure ideal for ducted systems and high-resistance environments.

Tube axial fans are ideal for confined or ducted zones like paint booths or tunnels, as they are compact and offer controlled, directional airflow with medium-pressure capabilities.

You can improve energy efficiency by selecting fans with modern, aerodynamic blades and energy-efficient motors. Implementing Variable Frequency Drives (VFDs) and IoT sensors for optimized performance and predictive maintenance also reduces power consumption.

Centrifugal fans are recommended for facilities with long ductwork or high resistance, as they are specifically designed to handle and maintain high air pressure efficiently across long distances.