- Gala No. 19, 2nd Floor,

Bail Bazar, Mumbai, India - +91 88 5002 0455

info@alfafans.in

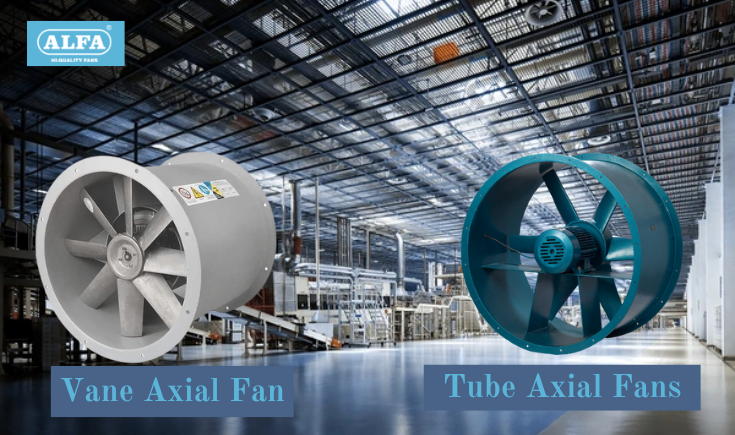

When it comes to industrial ventilation and air movement, selecting the right type of fan is critical for efficiency and performance. In a variety of applications—from HVAC systems to industrial manufacturing processes—fans are indispensable in maintaining airflow and controlling air pressure. Among the many fan types available, two prominent designs are

The tube axial fan is one of the most commonly used fans in industrial settings. As the name suggests, tube axial fans are designed with a cylindrical housing or casing that encloses the fan blades. These fans operate by drawing air in through the intake and pushing it through the fan blades, causing the air to flow along the axis of the tube. The motor in these fans is typically placed at one end of the fan casing, while the blades are located in the central section, allowing for efficient air movement.

The design of a tube axial fan is relatively simple, with a motor that drives the fan blades, creating an axial airflow. Air is drawn into the fan through one side and expelled from the opposite side. The airflow direction is aligned with the axis of the fan, making it highly efficient for moving large volumes of air at moderate pressures. Tube axial fans are generally used in applications where the volume of air is more critical than the pressure, such as in ventilation, cooling, and exhaust systems.

In terms of performance, tube axial fans are well-suited for environments where space constraints are not a primary concern. They are commonly used in applications like factory ventilation, heating, and cooling systems, and even in agricultural settings for climate control.

The simplicity and cost-effectiveness of tube axial fans make them an attractive choice for many industries. Some of the key advantages include:

Tube axial fans are designed to provide high airflow at relatively low pressures, making them ideal for large-volume air circulation.

Tube axial fans are compact, making them suitable for tight spaces in many industrial and commercial settings.

The manufacturing process for tube axial fans is relatively simple, which translates to lower production costs. This makes tube axial fans an affordable choice for many applications.

These fans can be used in a wide range of environments, from agricultural ventilation to industrial exhaust systems.

Vane axial fans, while similar to tube axial fans in that they operate on the same principle of axial airflow, differ in a few key design aspects. The distinguishing feature of

Vane axial fans are also equipped with a motor that drives the fan blades, but in addition to the blades, the fan contains a series of guide vanes. These vanes are installed inside the fan casing and are designed to straighten the airflow, improving the overall performance of the fan. This streamlined airflow leads to higher pressures, which means that vane axial fans can operate more efficiently in situations requiring high air pressure.

Unlike tube axial fans, which are generally used in low-pressure systems, vane axial fans are capable of handling higher static pressures and are, therefore, suitable for applications that require more controlled and focused airflow. These fans are commonly used in industries such as ventilation systems for large buildings, air conditioning units, and large-scale industrial processes.

The vane axial fan’s added vanes allow it to outperform tube axial fans in specific applications. Some of the primary advantages of vane axial fans include:

Vane axial fans can handle higher air pressures, making them ideal for environments where air needs to be moved over longer distances or through complex ductwork.

The vanes help guide the airflow, which enhances the fan’s efficiency by reducing turbulence and minimizing energy loss.

Due to their ability to operate at higher pressures with less energy consumption, vane axial fans are often considered more energy-efficient than tube axial fans, especially in applications where pressure control is necessary.

Vane axial fans tend to last longer in demanding environments due to their robust design, making them ideal for industrial use.

The primary difference between tube axial and vane axial fans lies in their ability to handle airflow and pressure. Tube axial fans are designed to move large volumes of air at relatively low pressures, making them suitable for applications that prioritize airflow over pressure. On the other hand, vane axial fans are designed to handle higher pressures, making them ideal for applications that require more controlled airflow and the ability to overcome resistance in the system.

Due to the addition of vanes in the casing, vane axial fans tend to be more efficient than tube axial fans. The vanes help direct the airflow in a more streamlined manner, reducing turbulence and improving energy usage. This makes vane axial fans better suited for environments where both high airflow and higher pressure are required, such as large ventilation systems or air handling units.

Tube axial fans are generally more compact and simpler in design, making them suitable for applications with limited space. Vane axial fans, due to their more complex design with the vanes inside the casing, are slightly larger and require more space for installation.

Tube axial fans are ideal for applications requiring large volumes of air with relatively low pressure, such as factory ventilation, agricultural settings, and air cooling. Vane axial fans, however, are better suited for high-pressure applications, such as HVAC systems in large buildings, industrial exhaust systems, and processes that require controlled airflow.

Tube axial fans are often more cost-effective than vane axial fans due to their simpler design and lower manufacturing costs. Vane axial fans, with their additional components, tend to be more expensive but offer greater efficiency in high-pressure applications.

When selecting a fan for your industrial needs, it’s important to choose a reputable manufacturer that offers high-quality, durable, and efficient solutions. Alfa Fans is one such brand that has made a significant impact in the fan industry. Known for their innovative approach and reliable products, Alfa Fans specializes in a wide range of fan types, including both tube axial and vane axial fans.

Alfa Fans provides custom solutions tailored to the specific needs of their clients, whether it's for general ventilation, exhaust systems, or more specialized applications like cooling towers and air handling units. The company’s expertise in fan design and manufacturing ensures that each fan is optimized for maximum efficiency and longevity, making Alfa Fans a trusted partner for industries across the globe.