- Gala No. 19, 2nd Floor,

Bail Bazar, Mumbai, India - +91 88 5002 0455

info@alfafans.in

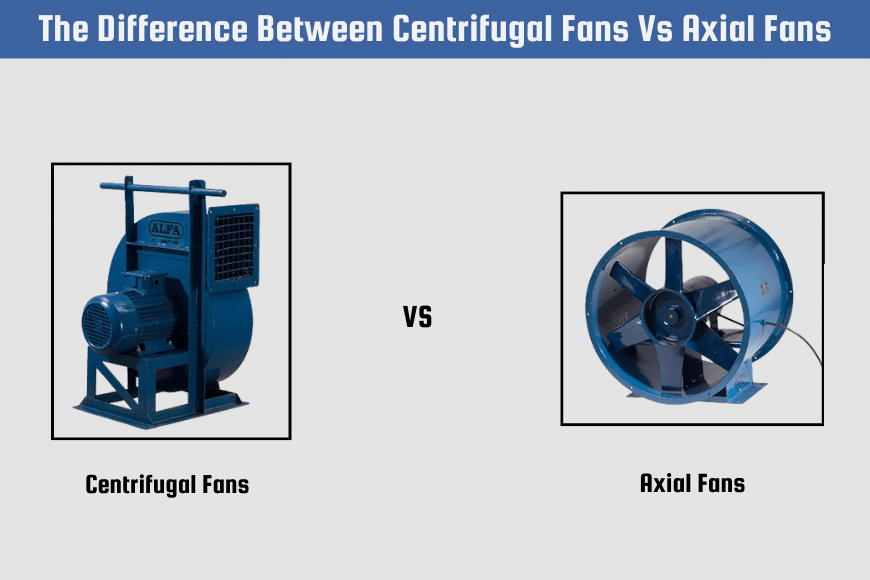

In the world of industrial air movement, the choice between centrifugal fans and axial fans stands as a critical decision for countless applications. As one of the leading

Let's talk about centrifugal fans first. These fans work by drawing air into the center of the fan and then expelling it outward at a different angle. This change in airflow direction generates increased pressure, making centrifugal fans perfect for applications requiring a steady airflow against higher pressure. Industries like HVAC systems, air pollution control, and various industrial processes benefit from these fans.

The key strength of centrifugal fans lies in their ability to handle different airflows, adapt to systems with resistance, and maintain consistent airflow even when faced with obstacles or changes in duct size. This versatility is a boon in industries demanding precise control of air movement.

On the other hand, axial fans operate differently. They move air parallel to the fan's shaft, pulling it through the fan blades and pushing it out in the same direction. Axial fans excel in applications where a high flow rate of air against low pressure is needed. Think of cooling towers, condensers, and ventilation systems where these fans play a crucial role.

Their straightforward design—a set of blades mounted on a central hub—makes axial fans reliable, cost-effective, and easy to maintain. They are best suited for scenarios requiring consistent airflow without significant resistance.

Key differences between axial fans vs centrifugal fans

:

The main differences between centrifugal and axial fans lie in how they generate airflow and handle pressure. Centrifugal fans alter airflow direction to generate pressure, making them ideal for systems with resistance. In contrast, axial fans move air in a straight line along the shaft, perfect for applications needing higher airflow against minimal resistance.

As prominent centrifugal fan manufacturers in India, Alfa Fans recognizes the importance of offering a wide range of both centrifugal and axial fans. This variety ensures industries can find the right solution that matches their specific requirements, be it handling high pressure or maximizing airflow.

Selecting between centrifugal fans and axial fans boils down to understanding your industrial needs. Factors like pressure, airflow volume, space availability, and energy efficiency play a crucial role in determining the right fan type for your application.

At Alfa Fans, we're committed to providing tailored solutions for your industrial airflow needs. Our diverse range of centrifugal and axial fans ensures that you'll find the most efficient, reliable, and suitable option for your specific requirements.

To summarize the dynamic world of industrial fans, understanding the differences between centrifugal and axial fans is pivotal. As an established industrial fan manufacturer in India, Alfa Fans offers expertise and a wide array of options. Whether it's centrifugal fans for systems requiring higher pressure or axial fans for applications prioritizing higher airflow, we're here to assist you in making the right choice.

Remember, selecting the perfect fan type should align with your industrial demands. With guidance from trusted manufacturers like Alfa Fans, finding the ideal fan for your specific needs becomes an easier task.